Product Details

Get a Free Quote

Remote Monitoring

Achieve continuous, measurable quality control with Tensitron transducers for fiber and wire.

Permanently mount the sensors and convert the tension to a reliable signal that can be output for remote display, high-speed recording, or automatic tension control. Transducers can be customized for your specific material or environment. For example, we can change the roller type and dimensions, or incorporate your own rollers.

Shown below are some of Tensitron’s standard line of transducers which range from 1/10th gram to 500 lbs. Many models are available. Transducers can be customized to meet your needs.

Are you interested in the Transducers Operating Manual? Just Fill Out Our "Get a Quote" Form.

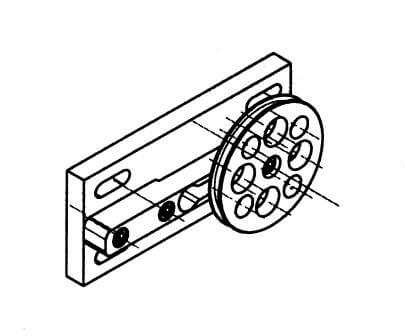

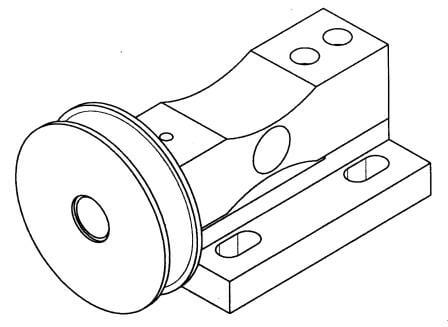

Small Space Transducer With Single Roller

Tension Range = 5 – 5,000 g

P/N: E-415-002

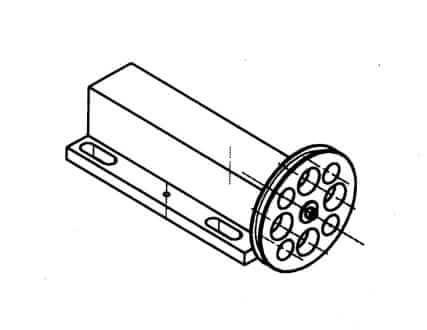

Platform Mounted Fiber Transducer

Tension Range = 5 – 5,000 g

P/N: F-1806

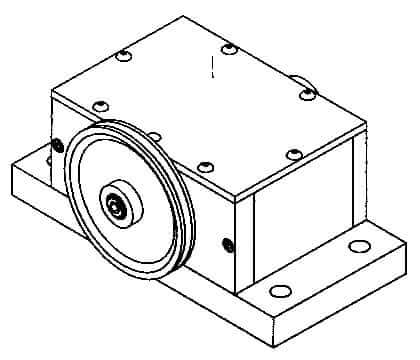

Single Roller Low Force Load Cell

Tension Range = 1 – 100 lb.

P/N: E-090-00

Tensitron’s Low Force Load Cells can be gauged to measure tension up to 150 lbs.

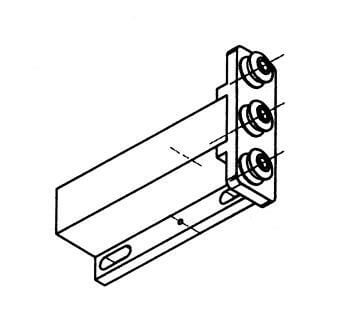

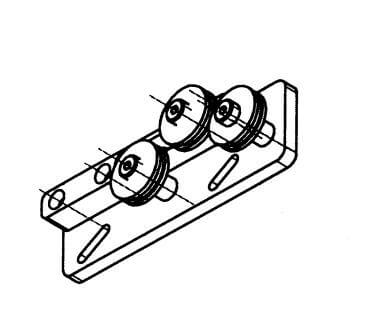

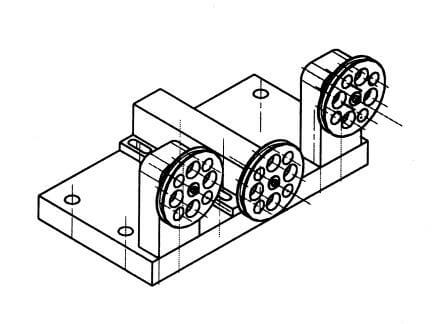

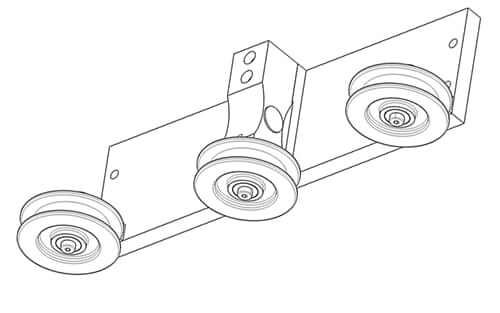

3 Roller Low Force Load Cell

Tension Range = 1 – 100 lb.

P/N:E-091-00

Notched Beam Transducer

Tension Range = 10 – 1,000 lb.

P/N: E-095-01

Tensitron’s Notched Beam Transducers measure up to 1,000 lbs tension over several models.

3 Roller Notched Beam Transducer

Tension Range = 10 – 1000 lb.

P/N: E-095-03